Railway Bearings

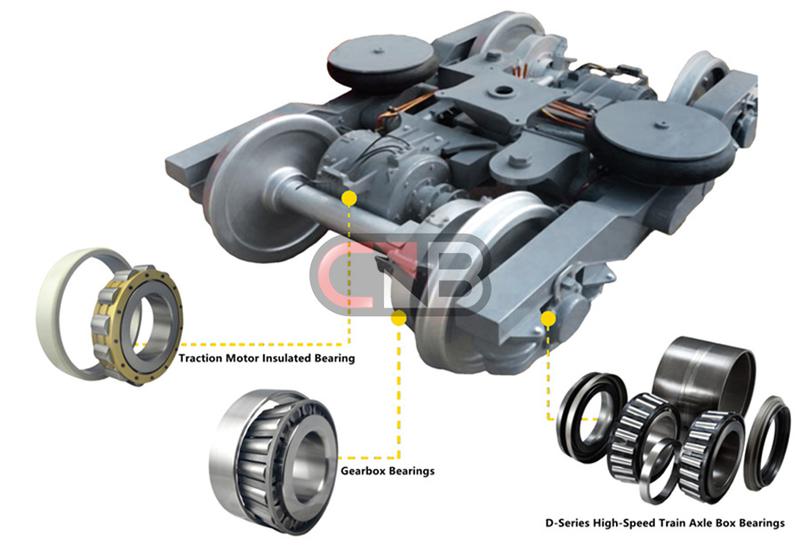

Railway rolling stock bearings refer to bearings used in locomotives. Bearings in locomotives include:

- Axle box bearings.

- Traction motor bearings.

- Transmission system bearings.

- Power unit bearing.

- Cooling system bearing.

The bearings in railway vehicles are mainly axle box bearings, and passenger car axle boxes mostly use short cylindrical roller bearings. The axle box of the truck mainly adopts tapered roller bearings. The variety, structure, and performance of these vehicle bearings are similar to those of locomotive axle box bearings.

1.Axle Box Bearing

The locomotive wheel is connected to the locomotive body through the axle box, spring, and bogie frame. The axle box bearing bears the gravity on the pressure spring of the locomotive and the radial and axial impact of the steel rail on the wheel. In addition, the bearing also transmits traction. As a result of some additional loads, the axle box bearing must have a larger load-bearing capacity, withstand shock and vibration, and have a long working life, safety, and reliability, smaller size; easy to inspect and maintain. Therefore, locomotive bearings often use non-standard series of bearings and special bearing technical conditions. Rolling bearings commonly used in locomotives fall into the following three categories:

Cylindrical Roller Bearings

Cylindrical roller bearings are used in most axle boxes of diesel locomotives and electric locomotives. There are two main types of bearings.

-

Four-row Cylindrical Roller Bearings

The earliest used and largest number of four-row cylindrical roller bearings (Bearing number:972832) have been installed in axle boxes for locomotives bearings in China. The bearing has a high load-carrying capacity and long-serving life, and its rated dynamic load is 1445kN. Since it can only bear radial load and cannot bear axial load, a device for bearing axial force must be provided in the axle box.

-

Double-Row Cylindrical Roller Bearing

Dong Fang Hong model 2,3,5,21 and Beijing locomotive axle boxes are all using Double-row cylindrical roller bearing:982832T. This bearing bears the radial load, while the angular contact ball bearing (146132T type) bears the axial load.

Although the above two types of bearings are used satisfactorily, they require a thrust bearing and a buffer device, so the overall components are large in weight, high in price, and complex in structure, and the failure rate is relatively high. Actually, the axial load of the axle is not very large, and the action time is short, and the cumulative action time is generally only 3% of the total running time. In addition, the axle box is air-cooled during operation, and the bearing temperature rise is not too high. Therefore, many foreign locomotives use two sets of single-row cylindrical roller bearings with retaining rings on the inner ring. The axle boxes (including the axle boxes of passenger cars) produced by Chinese locomotive manufacturers gradually adopt this kind of bearings. On six-axle locomotives, 1, 3, 4, and 6-position axle boxes are equipped with bearings 552732QT on the inside and 752732QT on the outside; 2, 5-position axle boxes are fitted with 552732QT on the inside and 652732QT on the outside. To ensure its strength and good service life, this type of bearing uses vacuum degassed steel or electro slag remelted steel and adopts some strengthening measures in the structural design, such as ring ribs with bevels, rollers with spherical end faces, with a convex roller (logarithmic roller), increase the diameter of the roller, improve the cages.

Spherical Roller Bearings

The advantage of using spherical roller bearings is that there is no need to design a tilt compensation device between the axle box and the bogie frame. The axle box bearing of the ND2 diesel locomotive imported from Romania is a C-shaped spherical roller bearing produced by SKF. Its model is equivalent to the Chinese bearing type: 3G4053736KT. The bearing rollers are symmetrical; its inner ring has no outer ribs; the middle flat retaining ring can be separated; the rollers and the outer ring are in line contact; the effective working length of the rollers is longer; its service life is slightly larger than the same outer contour size of asymmetrical spherical roller bearings.

Tapered Roller Bearings

This type of tapered roller bearing is used double-row tapered roller bearings in locomotive axle boxes. The USA ND5 diesel locomotive is equipped with AP-type bearings produced by TIMKEN. This type of bearing is in inch size; the commonly used bearings are B, C, D, E, F, and G grades used for different axles' rates.

2.Traction Motor Bearings

Traction Motor Armature Bearing

The traction motor is the main equipment in the transmission system of electric locomotive and electric drive diesel locomotives, and its armature bearing is one of its key components. The load of the armature bearing is large, and the size of the traction motor is restricted by the wheel diameter, the inner distance between the two wheels, and the lower limit of the locomotive. Therefore, this type of bearing must meet the requirements of smaller size and higher limit speed as much as possible.

-

Single-side Transmission Bearing

The armature is usually supported by a double fulcrum, the output end of the mounting gear is floating support, and the commutator end is positioning support. The output end bearing is located close to the gear and receives tremendous force. It is the key among the two bearings of the armature. NU-type cylindrical roller bearings with no ribs on the inner ring are generally used to reduce the load. The commutator end generally uses a NUP cylindrical roller bearing with a single inner ring and a flat retaining ring. There are also cylindrical roller bearings in foreign countries with a single inner ring and an oblique retaining ring.

-

Double-sided Transmission Bearing

When the motor power is large, if the single-sided transmission is still adopted, the bearing load at the gear is too large, and it isn't easy to select a bearing whose rated dynamic load and limit speed can meet the requirements. Therefore, the double-sided transmission is used under the conditions permitted by the motor design. The advantage of double-sided transmission is using helical cylindrical gears. The helix angles of the two gears are equal, and the rotation directions are opposite to obtain a relatively stable transmission quality without generating axial load. The bearing suitable for this purpose is the NU-type cylindrical roller bearing with no ribs on the inner ring. If spur gears are still used for the double-sided transmission, the bearing that can withstand a certain axial force should be selected. Generally, the bearing is an NJ-type cylindrical roller bearing with a single rib of the inner ring.

Traction Motor Axle-Holding Bearing

The Axle-suspended traction motor is usually supported on the bogie through an adjusting rod on one end. The other end is supported through axle-holding bearing on the wheel axle. It is relatively simple to adopt sliding support for axle hung bearings, but its lubrication and inspection are not convenient, so rolling bearings have been used since the 1950s. So far, cylindrical roller bearings, spherical roller bearings, and tapered roller bearings are still used.

Cylindrical roller bearings are suitable for high-speed locomotives. They have a long grease replenishment cycle and are relatively simple to install and maintain. This advantage can be fully demonstrated, especially when using an integral shell. The tapered roller bearing has good mounting rigidity, which helps to ensure the gear meshing accuracy, but its assembly and disassembly, adjustment of the axial clearance are difficult. The installation of two spherical roller bearings is more complex than tapered roller bearings, especially when disassembling, but it can adapt to the shaft's bending. Chinese traction motor for electric locomotive axle-holding bearings is using spherical roller bearings:3G3053148T.

Traction Generator Bearing

The engine body of the traction generator of modern electric drive diesel locomotives is usually installed on the end face of the engine body at the output end of the diesel engine. Regardless of this installation method or other methods, the input end of the armature is rarely using bearings. Generally, the armature is supported on the crankshaft or output shaft of the diesel engine through an elastic coupling to shorten the longitudinal dimension of the generator.

The outer end of the armature shaft generally uses cylindrical roller bearings. Sometimes, it is replaced with a spherical roller bearing to align with the diesel engine during installation.

3.Bearings for Diesel Locomotive Hydraulic Transmission System

The hydraulic transmission system of a diesel locomotive generally includes three parts: a hydraulic transmission box, a cardan shaft, and an axle gearbox. A Shunting locomotive sometimes consists of a working condition gearbox, which is equipped with many rolling bearings.

Hydraulic Transmission Box Bearing

The working method of the hydraulic transmission box is to convert the power of the diesel engine into the power to that of driving the locomotive through the hydraulic torque converter during the traction of the train; hydraulic brakes are used to absorb the kinetic energy of locomotive wheels. There are several bearings in the hydraulic transmission system, and rolling bearings support each shaft.

Intermediate Gearbox Bearing

The main components of the intermediate gearbox are the input shaft and output shaft of two gears. The gear on one of the shafts is a shift gear. This shaft and the gear have a clutch mechanism, which can make one of the gears connect with the shaft and transmits power; the other gear is just idling in this case. Because the input torque is small, the shift gear and the clutch are often arranged on the input shaft, which is beneficial to reduce the size of the spline-clutch and the size of the bearing.

4.Diesel Engine Crankshaft Bearing

Diesel engine crankshaft bearing is limited to using rolling bearings for high-speed diesel engines. Its main advantages are:

- Small friction loss.

- High mechanical efficiency.

- Reliable work.

- Long service life.

- Convenient lubrication.

- Small oil radiator size.

The main disadvantages of using sliding bearings are :

- High price.

- Heavyweight.

- High technical requirement for assembling.

- Inconvenient maintenance and replacement.

- Loud noise.

For single-cylinder and double-cylinder small diesel engine crankshafts, grade 0 rolling bearings are mainly used; for high-speed and high-power diesel engine crankshafts, generally, only cylindrical roller bearings are used because of the heavy load.