New-Energy Vehicle Drive Motor Bearing

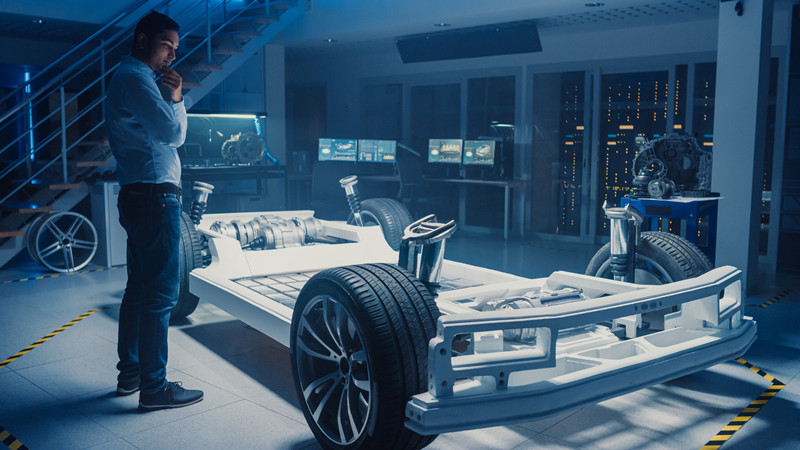

In 2021, the number of global new energy vehicles set a new record again. China is the world's major electric vehicle production base, and more and more automakers have formulated strategies to develop new energy vehicles in the Chinese market. With the rapid increase in sales of new energy vehicles, the market demand for drive motors has risen rapidly.

BS series bearings are designed and researched by C&U, which are high-speed bearings that are dedicated to new energy automobile drive motors. BS series bearings systematically use the new design, new technology, new material technology, and select special grease and cage material, so they not only have a comprehensive performance like longer life and higher reliability but also have low starting torque, high speed, and quick speed change, good sealing performance, free maintenance, etc.

Performance Advantages

- High Precision

- Meet temperature requirement of -40-150℃

- Low Vibration and low noise

- Low starting torque, low friction, and low-temperature rise

- Stable performance under high-speed, quick speed change, and alternating impact load

- Long service life, high reliability

Technical Features

Dimension

The external dimensions of the drive motor bearing are the same as those of the standard bearing, which meets the requirements of ISO external dimensions.

Tolerance

Bearing tolerances comply with GB/T 307.1 (ISO 492) standard tolerance requirements.

Clearance

Basic radial clearance of driving motor bearing is C3, if customers have other clearance requirements, please contact CNB for customer service.

Seal and Speed

Driving motor bearing adopts a non-contact seal structure. We can provide shield or rubber seal two kinds of sealing structures. Driving motor bearing speed is limited. Its rotation speed is restricted by bearing material and grease. Bearing speed under limit working temperature depends on heat generated by bearing, and bearing heat-related to bearing size, internal design, load, lubrication, etc. The limit speed has been listed in our product catalog.

Material and Heat-Treatment

Driving motor bearing rings adopt special C&U vacuum smelting bearing steel, which has characteristics like high reliability, long life, and impact resistance features, etc.

Cage material adopts high-strength engineering plastic. It can have superior performance under the condition of high temperature, high speed, start-stop repeatedly.

Driving motor bearings adopt special heat treatment technology, which can ensure its dimensional stability performance under the temperature of 150℃.

| Bearing Type | Dimensions(mm) | Basic Load Ratings(KN) | Limiting Speed | Reference Weight | |||

| Cr | C0r | RPM | kg | ||||

| BS6006-2RZ ( 2Z ) | 30 | 55 | 13 | 11.9 | 7. 50 | 18000 | 0. 133 |

| BS6007-2RZ ( 2Z ) | 35 | 62 | 14 | 13. 90 | 9. 30 | 16000 | 0. 153 |

| BS6008-2RZ ( 2Z ) | 40 | 68 | 15 | 15.2 | 11. 10 | 15000 | 0. 206 |

| BS6008X5 -2RZ ( 2Z ) | 40 | 68 | 18 | 15. 13 | 11. 15 | 15000 | 0. 237 |

| BS6009-2RZ ( 2Z ) | 45 | 75 | 16 | 19. 90 | 14. 00 | 15000 | 0. 230 |

| BS6010-2RZ ( 2Z ) | 50 | 80 | 16 | 20. 70 | 15. 80 | 12000 | 0. 273 |

| BS6011-2RZ (2Z) | 55 | 90 | 18 | 30. 86 | 22.43 | 12000 | 0. 368 |

| BS6012-2RZ ( 2Z ) | 60 | 95 | 18 | 28 | 21.5 | 11000 | 0. 388 |

| BS6013-2RZ ( 2Z ) | 65 | 100 | 18 | 29.2 | 23. 50 | 9000 | 0. 409 |

| BS6014-2RZ ( 2Z ) | 70 | 110 | 20 | 38 | 31 | 8000 | 0. 604 |

| BS6015-2RZ ( 2Z ) | 75 | 115 | 20 | 39.5 | 33. 50 | 7500 | 0. 649 |

| BS6016-2RZ ( 2Z ) | 80 | 125 | 22 | 47.5 | 40. 00 | 7000 | 0. 854 |

| BS6206-2RZ ( 2Z ) | 30 | 62 | 16 | 17. 90 | 10. 90 | 18000 | 0. 205 |

| BS6207-2RZ ( 2Z ) | 35 | 72 | 17 | 25. 70 | 15. 30 | 15000 | 0. 285 |

| BS6208-2RZ ( 2Z ) | 40 | 80 | 18 | 29. 10 | 17. 90 | 15000 | 0. 354 |

| BS6209-2RZ ( 2Z ) | 45 | 85 | 19 | 31.2 | 20. 30 | 15000 | 0. 403 |

| BS6210-2RZ ( 2Z ) | 50 | 90 | 20 | 33.2 | 23. 00 | 12000 | 0. 445 |

| BS6211-2RZ ( 2Z ) | 55 | 100 | 21 | 39. 10 | 26. 50 | 12000 | 0. 603 |

| BS6212-2RZ ( 2Z ) | 60 | 110 | 22 | 52.5 | 36. 00 | 11000 | 0. 783 |

| BS6215-2RZ(2Z) | 75 | 130 | 25 | 67.4 | 48. 30 | 7000 | 1.24 |

| BS6218-2RZ(2Z) | 90 | 160 | 30 | 101.2 | 71.5 | 6300 | 2. 150 |

| BS6305-2RZ(2Z) | 25 | 62 | 17 | 21.2 | 10. 90 | 18000 | 0. 236 |

| BS6306 -2RZ( 2Z ) | 30 | 72 | 19 | 27.3 | 16. 50 | 16000 | 0. 353 |

| BS6307-2RZ(2Z) | 35 | 80 | 21 | 29. 10 | 17. 60 | 15000 | 0. 485 |

| BS6308 ~2RZ(2Z) | 40 | 90 | 23 | 40. 40 | 25. 50 | 15000 | 0. 636 |

| BS6309 -2RZ(2Z) | 45 | 100 | 25 | 48.9 | 29. 60 | 13000 | 0. 832 |

| BS6311-2RZ(2Z) | 55 | 120 | 29 | 71.5 | 45. 00 | 10000 | 1.37 |

| BS6313-2RZ( 2Z ) | 65 | 140 | 33 | 92.5 | 60. 00 | 8500 | 2. 118 |

| BS6314-2RZ( 2Z ) | 70 | 150 | 35 | 104. 00 | 68. 00 | 8000 | 2. 527 |

| TD6315-2RZ(2Z) | 75 | 160 | 37 | 114. 00 | 76. 50 | 5000 | 3. 02 |

| TD6316-2RZ(2Z) | 80 | 170 | 39 | 129 | 86.9 | 4500 | 3. 59 |

The BS series new-energy vehicle drive motor bearings have reached the advanced international level of high-speed performance, temperature rise, grease leakage, fatigue life, and other tests.

Through the market application and verification of domestic well-known drive motor companies, our bearings can meet market demand and have received batch orders from domestic mainframe manufacturers. The C&U group has invested in multiple new energy automobile-bearing production lines.

At the same time, the product has been jointly developed with internationally renowned OEMs and successfully matched, especially in the high-speed performance design and test technology to achieve original innovation. This technology fills the domestic gap. In the field of new-energy vehicle drive motor bearings, it replaces import bearings and leads the development of the industry.

The traditional automotive bearing industry faces new challenges. In the future, electric vehicles will save the engine, gearbox, transmission shaft, and other components of conventional fuel vehicles due to the electric drive mode. Some products such as traditional automotive bearings, generator bearings, water pump bearings, rocker bearings, and tensioner bearings face a reshuffle. New energy automotive bearings have brought new business opportunities and challenges to bearing companies.

The drive motor is one of the most critical components of new energy vehicles. The exclusive bearing of the drive motor is listed as the core technology and is one of the critical projects for China's auto parts industry to achieve leapfrog development. All this shows that low-carbonization, informatization, and intelligence have become the future automotive technology development trend. It is only a matter of time before new energy vehicles replace internal combustion vehicles.