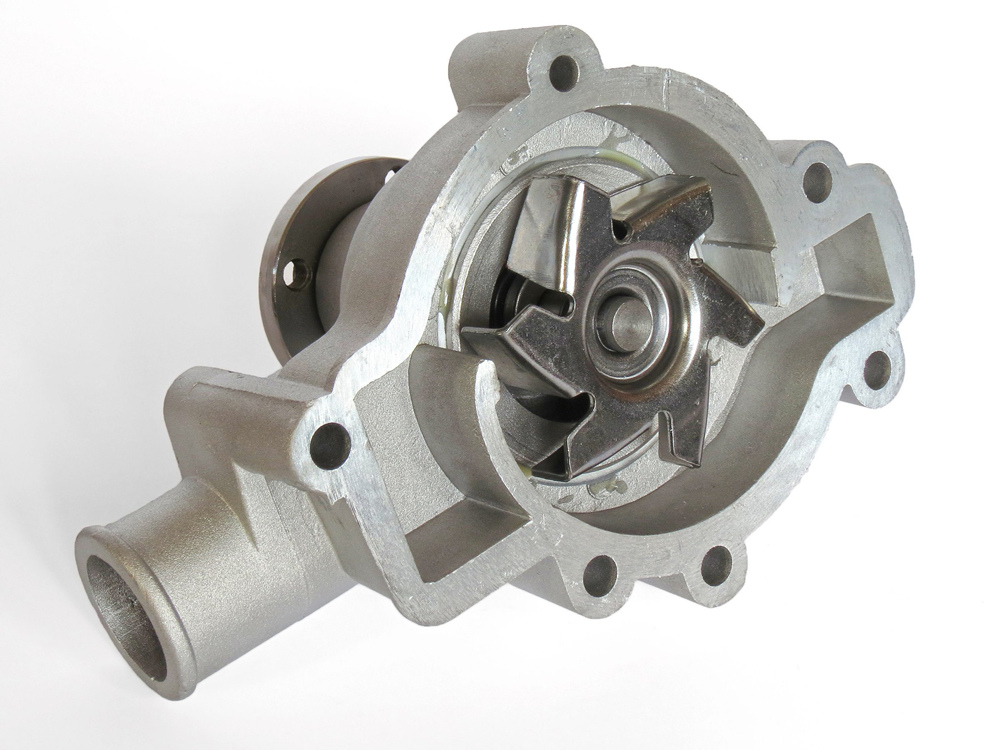

Water Pump Bearings

With the development of automobile to high speed, high reliability, and low energy consumption, automobile cooling water pump also needs to develop to the direction of lightweight, small volume and high speed, it has been widely used in the automobile industry because of its advantages of large capacity, good rigidity, high rotation, simple assembly, long service life and reasonable structure. At present, the water pump bearing can not only be used in automobile cooling water pumps, but also be used in textile machinery, construction machinery, and so on.

Shaft bearing is an important part of the water pump. Due to the high speed of the water pump, the speed of the general water pump is up to 6000r/min, and the speed of the high-speed water pump is up to 9000r/min. Therefore, the water pump bearing is required to have a high load-bearing capacity, so as to meet the requirements of the pump life at a certain speed. The spatial position of the water pump is restricted, the heat dissipation area is small, and the working conditions are bad. Therefore, the bearing should be able to meet the requirements of maintaining normal operation under high temperature without reducing the bearing capacity of the bearing. The sealing of the bearing has certain difficulties, and its seal reliability and durability will directly affect the usability of the water pump. In short, the bearing capacity, working clearance, and seals performance of the bearing are three important performance indicators that affect the performance of the water pump.

Material Selection

The steel balls and rollers of CNB water pump bearing are usually made of high chromium-bearing steel. The material of the shaft and the outer ring is made of carburized steel or high chromium-bearing steel. Shaft material used carburized bearing steel shaft raceway hardness is usually 60-64HRC; high chromium bearing steel shaft hardness is usually 58-62hrc; ball and roller hardness is 61-65hrc; outer ring hardness is usually 60-64HRC.

The material of the cage is reinforced nylon 66, and the seals are usually made of nitrile rubber. When the working temperature is over 120 °C, the fluorine rubber sealing ring should be chosen.

Clearance

The actual internal clearance of the water pump bearing in use greatly affects the service life and performance of the bearing. In selecting the original radial clearance, in addition to considering the clearance reduction caused by the interference fit between the bearing outer ring and the bearing housing bore, also consider the reduction of clearance due to thermal expansion of the component caused by temperature rise

When there is no special requirement, the original radial clearance of CNB pump bearing is 15-35ΜM

Lubrication and sealing

The water pump bearing uses the disposable grease “Lifelong” lubrication, therefore the lubrication directly influence bearing service life. Usually, 2-3 # lithium grease is used to meet the lubrication requirements, the amount of grease filling is 1/4-1/2 of the bearing inner space, and the seals adopt the optimized radial contact seal, to ensure that the bearings do not leak oil and external impurities invasion.

Installation

Water pump bearings are precision mechanical parts, we need to pay special attention when installing. Keep the bearing and the surrounding environment clean, the assembly tools should be clean, and check the shell, flange, impeller, and seals.

During installation, use auxiliary tools for mechanical press-in. It is strictly forbidden to transmit pressure through rolling elements. At the same time, avoid external impact to damage the bearing. The roundness of the water pump housing hole should be controlled within 10μm and the cylinder degree within 20μm.

Store

Compared with general mechanical parts, the water pump shaft bearing is a precision component, so special care should be taken when storing and using it.

CNB's water pump bearings are coated with an appropriate amount of anti-rust oil and packed with anti-rust before leaving the factory. As long as the packing is not damaged, the quality of the bearings will be guaranteed. When storing, it is appropriate to store it on a shelf 30cm above the ground under the condition that the humidity is lower than 65% and the temperature is about 20 degrees. In addition, the storage place should avoid direct sunlight or contact with cold walls