Dental Drill Bearing- High Speed Miniature Bearing

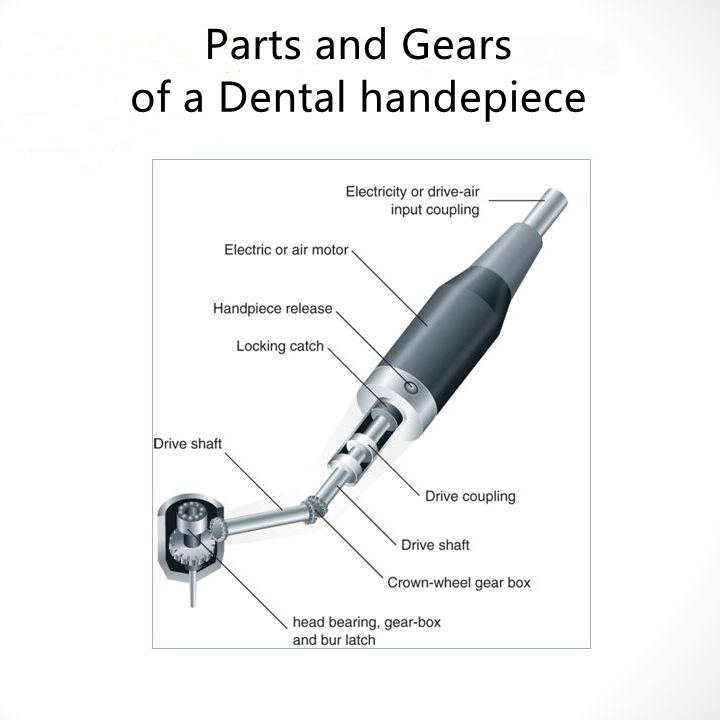

A key component of the dentist's handpiece is the high-speed dental drill component. High-speed turbine dental drill handpiece bearings are mechanical bearings composed of shafts, worm gears, spring chucks, spring washers, back covers, shells, rolling bearings, rubber positioning rings, and other parts. The rolling bearings used are called dental drill bearings. The turbine, the bearing, and the shaft are in an interference fit and are driven by compressed air to rotate at high speed, driving the spring chuck and the drill installed in the shaft hole to work.

The inner and outer rings of the dental drill bearing supplied by CNB are made of refined stainless steel (9Gr18); the steel balls are made of stainless steel (9Gr18) or non-metallic superhard ceramic (Si3N4) material, which has good wear resistance. The cage is made of polyimide or 80-120 phenolic cloth bakelite material with high strength, low wear resistance, and self-lubricating properties. Under the air pressure of 200~250Kpa, the rotating speed of dental drill bearing can reach 350,000~450,000rPm. Under normal conditions of use, the working life of dental drill bearings is more than six months.

The manufacturing precision of special bearings for high-speed dentist handpieces meets the P4 tolerance in the national standard GB/T307.1-94 and can be applied to different models of dentist handpieces worldwide. For example, NSK in Japan, W & H in Austria, Bein Air in Switzerland, Lares in Germany, KaVo in Germany, FARO, Midwest America, Adec, Yoshida, Siemens, and other brands of high-speed dental handpieces.

Model: SR144

Inner diameter: 3.175mm

Outer diameter: 6.350mm

Thickness: 2.380mm

Dental drill bearing material and characteristics

1. The bearing material is critical to its accuracy, performance, and working life. The bearing ring material of high-speed turbine dental drill mobile phone should be made of special corrosion-resistant stainless steel, the ball's material should be a Si3N4 ceramic ball with a small thermal expansion coefficient, and the material of the cage should be the compression, impact, and high-temperature resistant polyimide TORLON.

2. Strict bearing processing technology is the key to the product's success. CNB optimizes the processing technology of bearing rings according to the structural characteristics and technical requirements of high-speed dental drill bearings. Ensure proper technology retention, dust-proof structure, and critical characteristic parameters, and design a solid crown-shaped cage suitable for one-time processing of CNC lathes.

3. 450,000 rpm high speed. If the dental drill bit can reach a very high speed, it can reduce the patient's pain during the treatment of the teeth. 450,000 rotation per minute is an internationally recognized high speed that dental drill bearings can achieve. There are no more than five bearing manufacturers in the world that can meet this requirement. To produce high-quality dental drill bearings, we have done a lot of tests and experiments, and now CNB has been able to guarantee stable output and bearing quality.

4. In addition to the limit speed, whether the P4 / ABEC7 bearing accuracy can be achieved is another critical factor in measuring a bearing manufacturer's ability. Although many factories mark P4/ ABEC-7 accuracy on their products, once these bearings are operated, it is easy to find that they do not reach the corresponding accuracy level. Most of these low-end bearings have only an ABEC-3 accuracy level, and this is also why the price of some dental drill bearings is very low.

5. However, these low-quality dental drill bearings will greatly damage the dental drill handpieces and equipment. According to statistics, more than 50% of the bearing market is covered by counterfeit bearings. Due to the limitations of materials and production processes, the rigidity of these low-end bearings cannot meet national standards, which will shorten the service life of the equipment and cause damage to other components. The gap between different ABEC accuracy levels may also cause assembly difficulties and even scrapped entire equipment. MEET Bearing has become a significant domestic supplier of miniature bearings, and some of its products have genuinely reached the P4/ABEC7 level.

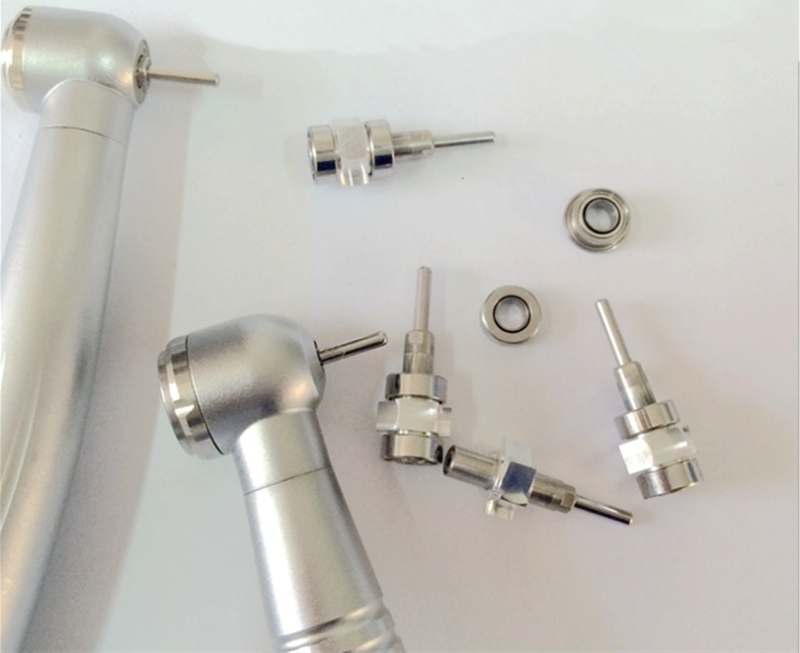

Dental drill bearing installation

When installing the dental drill bearing, the best matching interference between the internal control of the bearing and the shaft is 0~2μm. The circular deviation of the shaft should be less than 2μm. The force that presses the shaft into the inner hole of the bearing should directly act on the inner ring of the miniature bearing and not through the steel ball or the grooved sleeve of the ring so as not to damage the bearing accuracy. After installing a pair of bearings on the turbine, it is necessary to drip lubricating oil after the turbine, and the bearings are cleaned before being seated in the machine head (the cleaning fluid cannot use acetone or ethanol). When installing the dental drill bearing into the handpiece, a specific axial preload (1~2N) should be applied to a pair of bearings to obtain the ideal high-speed performance.

Specific steps:

1. Clean the outer surface of the head.

2. Insert the drill chuck.

3. Follow the steps below to clean the inside of the handpiece:

A. Clean with spray for 1 to 2 seconds.

B. Wipe impurities in the head with particular tissue.

C. Repeat the above two steps until it is immaculate.

D. Dry the liquid on the surface of the head.

E. Repeat the above actions until the surface liquid is completely wiped off.

4. Disinfect the handpiece according to the manufacturer's instructions.

5. Cool the machine head to room temperature.

6. Put two drops of lubricating oil into the driving air pipe.

7. Wipe off excess lubricating oil.

8. Wipe the outer surface.

9. Now, the dental drill handpiece is ready for use.

The user should be careful during installation to avoid damage to the ball and raceway. Bearing contamination and improper lubrication will directly affect performance indicators and service life.