Brief inroduction of Bearing Parts and Materials

Bearing Material

The most common material used in ball bearings, roller bearings, and tapered roller bearings is 52100 chrome steel (Gcr15 in Chinese standard). These materials are the bearings inner and outer rings, balls and rollers. The chemical composition of this steel has high carbon and about 1.5% chromium content. Using controlled processing and heat-treatment methods, the treated bearing components have high strength to resist cracking and a hard surface to resist subsurface rolling contact fatigue. The typical surface hardness for bearing components made from this material ranges from 60 - 64 on the Rockwell hardness C scale (Rc).

The raw steel which is used to produce high precision miniature bearings is processed with additional melting steps. The result is a type of steel with very uniform fine grain material structure, the bearing contact surfaces can be super finished very smooth so the bearing is very quiet.

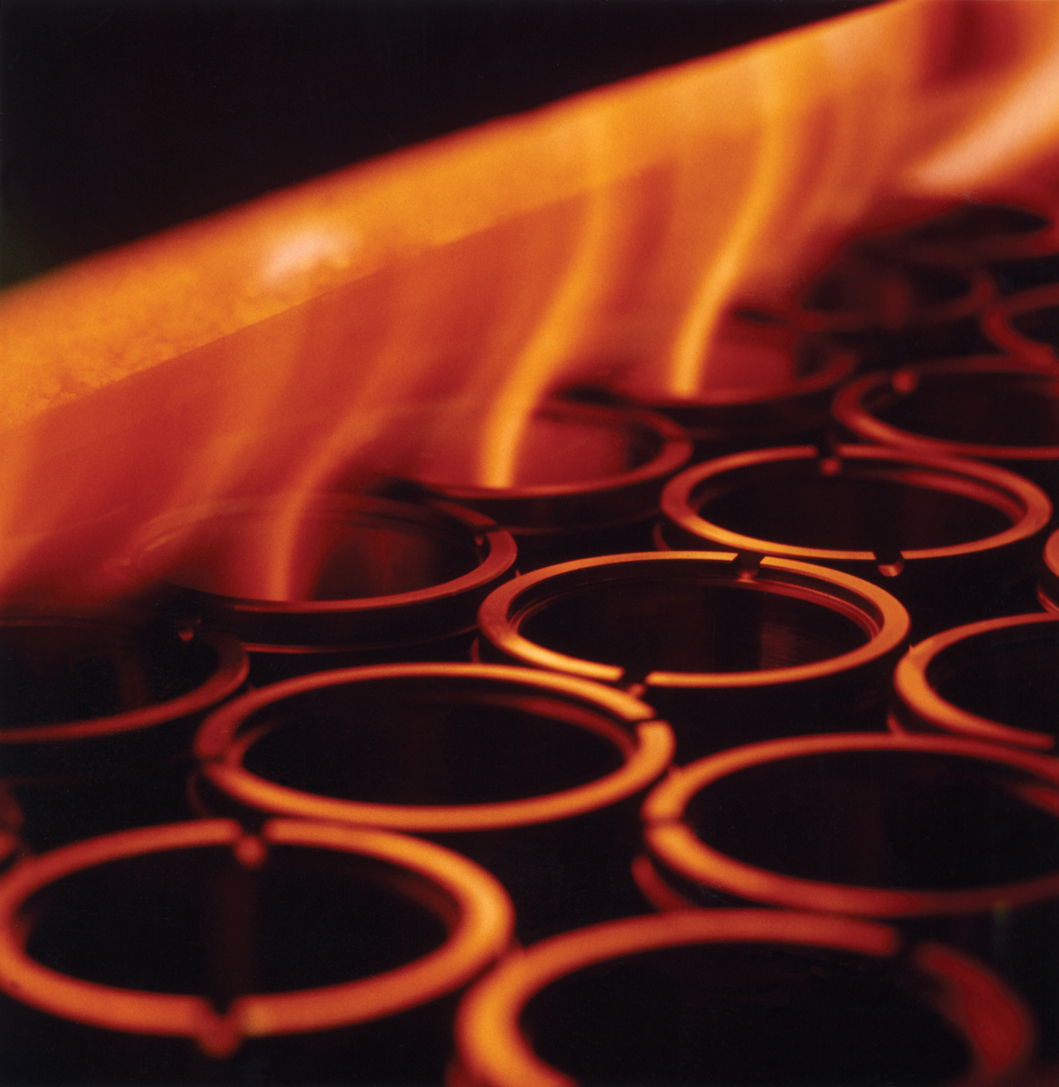

The most common heat treating method for chrome steel is to thru harden the steel in a controlled atmosphere furnace. Bearings being manufactured from chrome steel can operate at continuous temperatures up to 120°C.

Where higher temperatures are encountered, it is possible to heat stabilize the bearing components. By varying the heat treating process, bearings can be produced so they are capable of operating at temperatures of 220°C, and even higher. For these applications, the components must be subjected to a tempering treatment at a higher temperature corresponding to the service temperature. This elevated tempering treatment has a detrimental effect on the hardness of the material and the load carrying capacity of the bearing is reduced.

Bearing Parts materials

Cages

The most common cage material is brass and iron.

Plastic materials are sometimes used for bearing cages. The most common is molded nylon plastic but molded acetal (POM) is also used. Other polymers are used in special bearing designs where specific performance requirements such as high speed, or low torque or low noise are identified.

Cages made from phenolic (phenol-formaldehyde) materials are most common in high speed ball bearings used in machine tool equipment spindles. The phenolic cages are lightweight and have high strength. The cost of processing this material has led to an increase use of plastics in its place. Additional information is contained in the Cages technical bulletin.

Seals and Shields

Seals means RS/RZ in bearing numbers, and shileds are ZZ type(made by Iron) .The most common seal material is nitrile rubber or Buna rubber. It has good mechanical properties, can be used across a wide temperature range, is resistant to many chemicals and is low in cost. Materials such as Viton and Silicone are expensive elastomers and they’re usually used when an application requires their unique properties.

Bearings Made Of Ceramic Materials

Bearings made with ceramic materials fall into a specialty niche in the bearing industry. The most common arrangement is a hybrid bearing, usually with stainless steel rings and ceramic balls. The most common ceramic material used is silicon nitride. Balls made from this material are hard, up to Rc78, and have a very smooth surface. Hybrid bearings are more expensive than all stainless steel bearings.

Heat Treatment

When bearing steels are in their soft (unhardened) state, metallurgists refer to their structure as being in the pearlite state. In order to harden the steel it must be heated to a very high temperature and then cooled very rapidly. When heated in the heat treat furnace to 1,750°F, the structure transforms from pearlite to what is known as austenite. After quenching (very rapid cooling), the structure then transforms from austenite to martensite. Once transformed to martensite, the steel becomes very hard. However, at this point it is not considered "thermally stabilized". This is because not all of the austenite transforms into martensite during the quenching process. This phenomenon is called "retained "austenite".

If the steel is not thermally stabilized, the retained austenite will over an extended period of time (possibly years) transform into martensite. This transformation is accompanied by an increase in volume that is called metallurgical growth (not to be confused with thermal growth). Metallurgical Growth will cause a change in dimension and form of any steel parts such as bearings' even at room temperature.

While not a problem with low precision commodity type bearings, in high precision (ABEC 5P, 7P, 9P) miniature bearings this lack of dimensional stability can cause problems. In order to eliminate this unwanted metallurgical growth, the steel must be subjected to thermal stabilization. This is accomplished by repeated cycles of chilling at -120 F and tempering to transform a large percentage of the retained austenite to martensite.